Oil-Gas and Industrial Pipelines

IB Group offers high-quality piping systems for oil and gas extraction and industrial projects. Our products are resistant to high pressure, wear, and corrosion, making them ideal for long-term and efficient use in local and international projects.

Piping systems for oil and gas extraction and industrial operations

IB Group provides high-quality pipes to meet the specific needs of the oil, gas, and industrial sectors. These pipes are resistant to corrosion and capable of withstanding high pressure, manufactured in compliance with international standards such as API 5L, EN, and GOST.

Oil, gas, and industrial pipes are primarily designed for transportation, processing, and manufacturing processes. They are widely used in both offshore and onshore projects, including oil wells, gas pipelines, and industrial facilities. Their long-term durability and reliability make them an ideal choice for industrial projects.

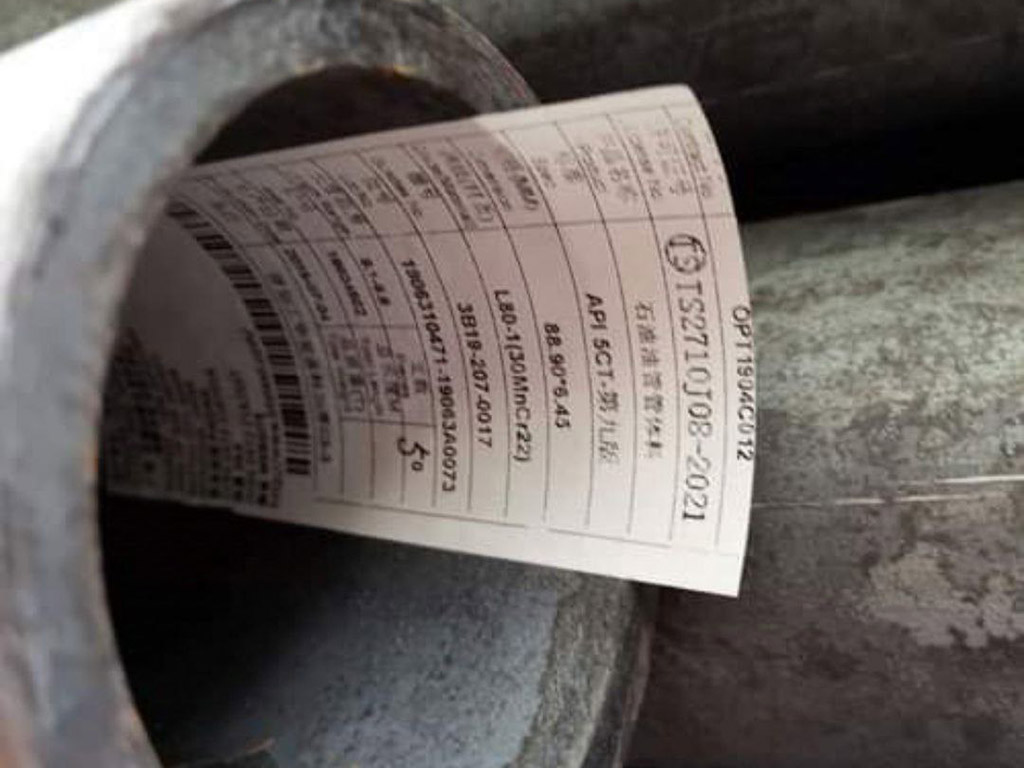

Oil Casing and Tubing Pipes - OCTG

Oil casing and tubing products are essential components in oil and gas extraction processes. These pipes ensure the safety of oil and gas wells, protecting them from mechanical impacts. Made from materials suitable for varying pressure and environmental conditions, these pipes offer high durability and long-term performance. With a range of standard and premium connectors, these products are versatile for various drilling operations.

Applications: Oil and gas wells, Deep drilling processes, Mechanical protection during drilling, Protection with casing pipes

- EN Standards

- GOST Standards

API 5CT, ISO11960

Ø10mm – Ø406mm

5mm – 25mm

J55, K55, N80, P110

BTC, EUE, Premium

Download PDF

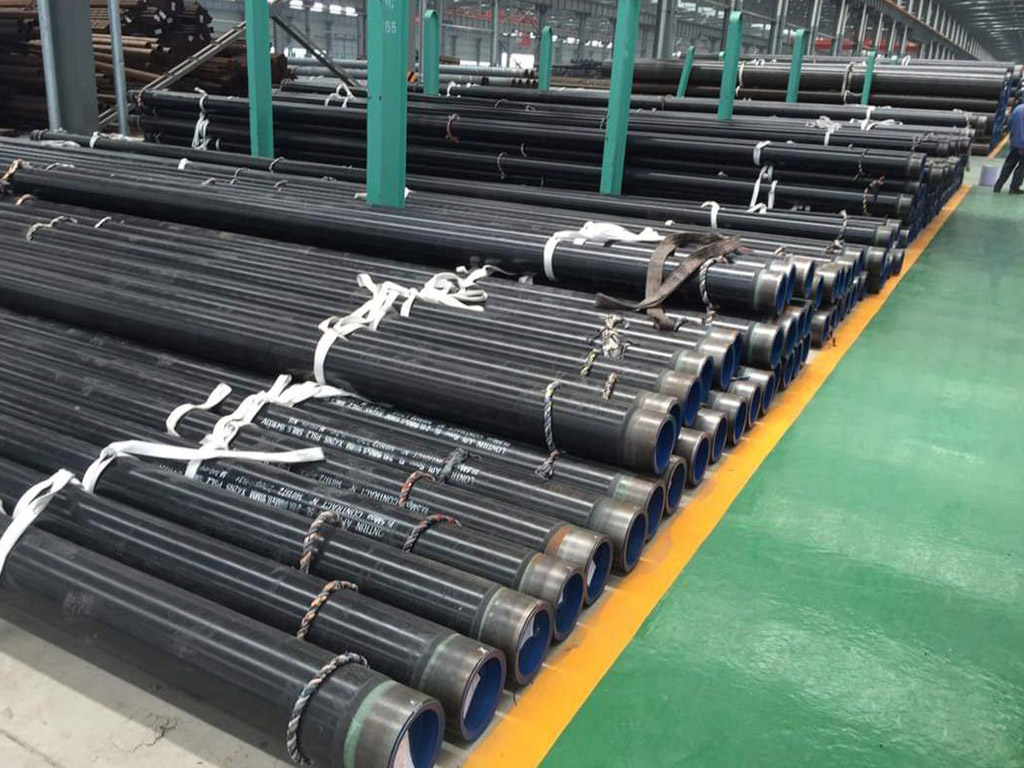

Seamless Steel Pipes

Seamless steel pipes are a vital component in industrial and engineering projects due to their high resistance to pressure, temperature, and mechanical stress. These pipes are manufactured using seamless processes, providing excellent mechanical properties and durability. The primary advantage of seamless pipes is the absence of welding seams, making them stronger and more reliable. They are available in a wide range of sizes and materials, catering to diverse applications.

Applications: High-pressure gas and water pipelines, Petrochemical industry, Heat pipes in power plants, Shipbuilding and mechanical engineering

- EN Standards

- GOST Standards

EN10216, EN10297

Ø6mm – Ø711mm

1mm – 40mm

P235GH, P265GH, 15Mo3

Seamless welding

Download PDF

High-Pressure Boiler Pipes

High-pressure boiler pipes are key components in industrial and energy production sectors. These pipes are specifically designed to operate under high-temperature and high-pressure conditions. The use of high-quality materials in their production ensures long service life and mechanical strength. They are widely used in power plants, high-pressure steam systems, and petrochemical complexes. Their excellent corrosion resistance and adaptability to temperature variations enhance safety and efficiency. The ability to withstand high pressure ensures reliability in critical operations.

Applications: Power plants, Petrochemical industry, High-pressure steam systems, Aviation and nuclear industries

- EN Standards

- GOST Standards

EN10216, ASTM A335

Ø10mm – Ø530mm

2mm – 80mm

620°C

15CrMoG, 12Cr1MoVG, P91

Download PDF

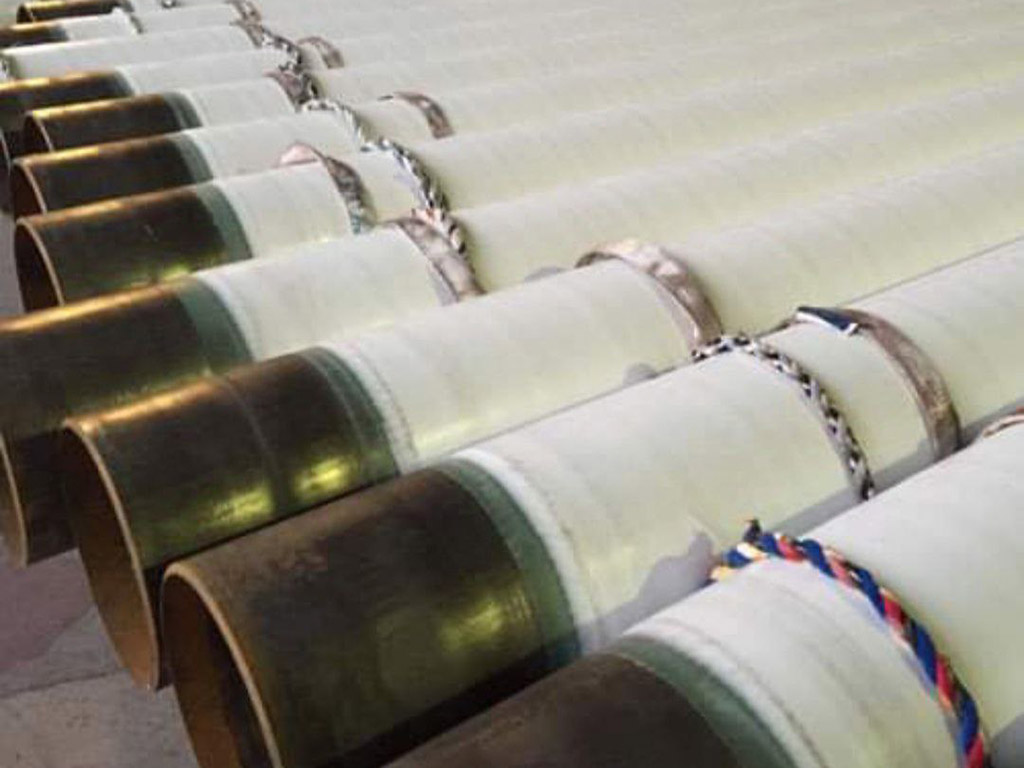

Anti-Corrosion Coated Pipes

Anti-corrosion coated pipes are high-quality products that ensure durability and safety during the transportation of water, gas, oil, and chemicals. The special coating technology protects these pipes from chemical impacts, moisture, and corrosion even in harsh environments. Widely used in both underground and above-ground projects, particularly in industrial and marine infrastructure, these pipes offer energy efficiency and require minimal maintenance due to the use of modern materials and technologies.

Applications: Water and gas pipelines, Marine infrastructure, Transportation of chemicals, Underground and industrial projects

- EN Standards

- GOST Standards

EN ISO 21809-1, EN 10289

3-layer PE, FBE

Ø20mm – Ø1200mm

-30°C – +100°C

150 bar

Download PDF

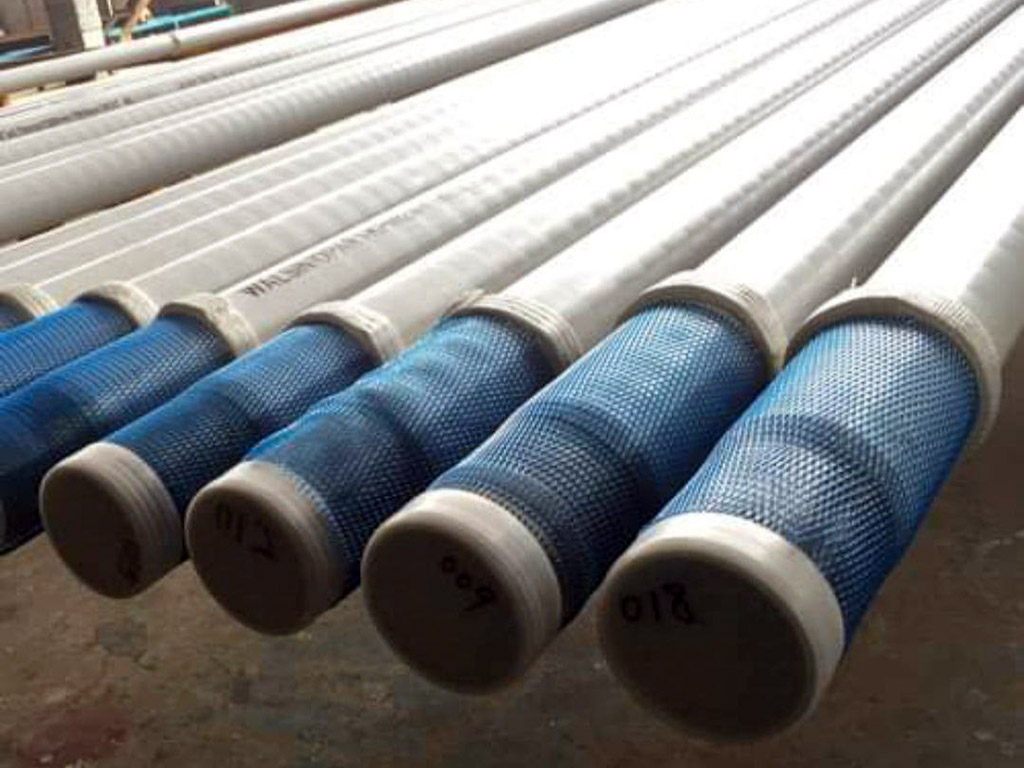

Coated and Insulated Pipes

Coated and insulated pipes are essential components in engineering and industrial projects. These pipes provide superior thermal protection and long-lasting corrosion resistance through a specialized polyurethane insulation process. The insulation is achieved by injecting polyurethane between the inner carrier pipe and the outer shell. These pipes are widely used in marine environments, oil and gas pipelines, and underground construction projects.

Applications: Water and gas pipelines in marine environments, Underground construction projects, Oil and gas transportation, HVAC and heating systems

- EN Standards

- GOST Standards

EN253, EN10217

Ø20mm – Ø1600mm

3mm – 20mm

Polyurethane foam

Polyethylene or polypropylene

Download PDF

Special Purpose Pipes

Special purpose pipes are specifically designed products to meet certain industrial and technical requirements. These pipes are effectively used in various conditions, including high pressure, temperature, and exposure to chemical environments. Unique materials and production technologies are applied in their manufacture, ensuring durability and reliability. Special purpose pipes are widely utilized in sectors ranging from energy to aerospace industries.

Applications: Aerospace industry, Energy sector and heating systems, Petrochemical industry, Specialized engineering projects

- EN Standards

- GOST Standards

EN10255, EN10296

Ø10mm – Ø1200mm

1mm – 30mm

316L, 321, Inconel 625

Anti-corrosion and high-temperature coating

Download PDF

Other products

Modern solutions for railway infrastructure. High-quality production that meets international standards. The perfect choice for safety and durability in railway transportation.

Fish plates provide modern solutions to ensure the safety and durability of railway tracks. Manufactured in compliance with international standards and high-quality requirements, fish plates deliver maximum performance and resilience in regional and international railway projects.

High-Quality Railway Accessories for Modern Rail Systems

Strategic elements for industry and technology.